MK1 RS2000 project

Moderator: Moderators

Re: MK1 RS2000 project

John Mc ( Yorkshire POM in Perth WA)

- MOOSE

- Open - C4 License

- Posts: 290

- Joined: Tue Jul 17, 2007 7:15 pm

- Location: Perth

Re: MK1 RS2000 project

I'll have a look at my genuine sheets in the morning

-

Danny M - Seasoned Racer

- Posts: 2743

- Joined: Sat Jan 07, 2006 8:24 am

- Location: Brisbane, Qld

Re: MK1 RS2000 project

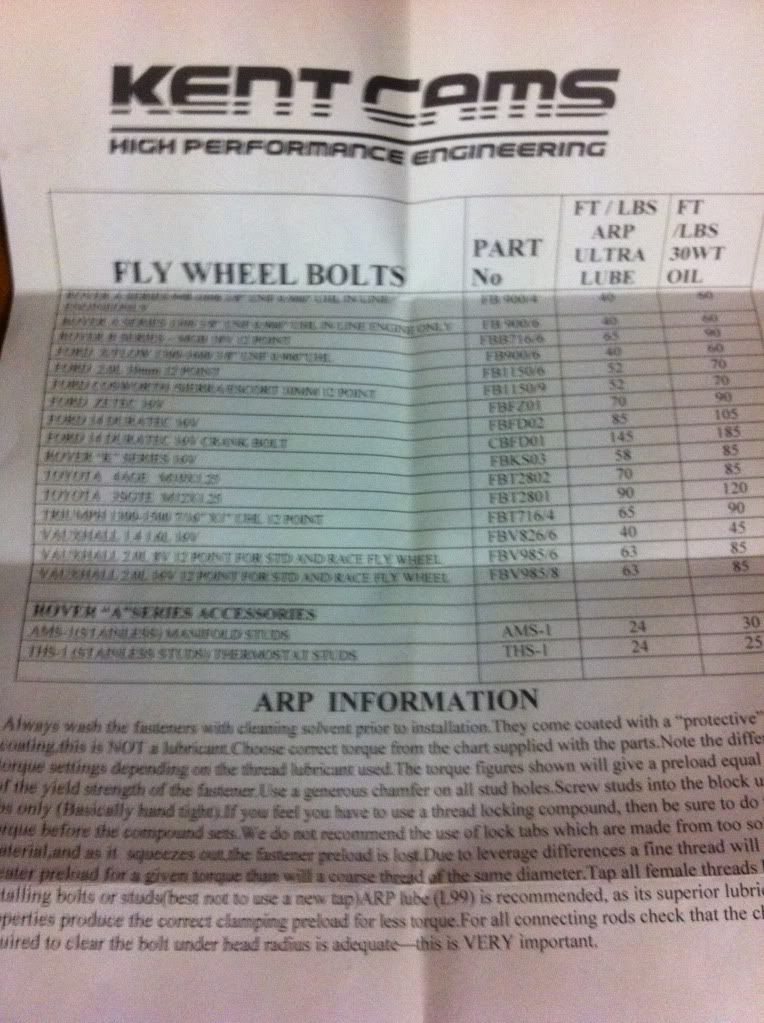

151-2801 Pinto flywheel bolts

49 ft/lbs with moly

64ft/lbs with 30 wt

The only reason to over tighten a fastener from spec is if it can be measured for stretch.

I have never had an ARP fastener problem in any application.

Have you ever had your torque wrench calibrated?

49 ft/lbs with moly

64ft/lbs with 30 wt

The only reason to over tighten a fastener from spec is if it can be measured for stretch.

I have never had an ARP fastener problem in any application.

Have you ever had your torque wrench calibrated?

- Paul T

- P Plater - C3 License

- Posts: 202

- Joined: Mon Apr 28, 2008 10:52 pm

- Location: Sydney

Re: MK1 RS2000 project

Paul T: go to the ARP-Bolt wbesite and check their instructions for 151-2801

http://arpinstructions.com/instructions/151-2801.pdf

"Part Number: 151-2801

Application: FORD 2000cc PINTO

Flywheel Bolt without Washer- Installation

[1] Please check the part-number(s) for your application

against the part-number(s) listed on the instruction

sheet.

[2] DO NOT USE ANY WASHERS with ARP Flywheel

Bolts. They are designed to be installed without

them. Note: ARP will NOT be responsible for any

failures resulting from using a washer with this kit.

[3] Make sure there is an adequate chamfer around the

bolt holes on the flywheel to clear the radius under

the head of the bolt.

[4] Lubricate the threads of the bolt with LOCTITE 242

and the under head of the bolt with ARP ULTRATORQUE

FASTENER ASSEMBLY LUBRICANT.

Then install the flywheel onto the crankshaft and

tighten the bolts hand tight.

[5] Using an alternating or criss cross pattern, torque the

bolts to 70 ft lbs using the specified lubricants

in Step 4."

http://arpinstructions.com/instructions/151-2801.pdf

"Part Number: 151-2801

Application: FORD 2000cc PINTO

Flywheel Bolt without Washer- Installation

[1] Please check the part-number(s) for your application

against the part-number(s) listed on the instruction

sheet.

[2] DO NOT USE ANY WASHERS with ARP Flywheel

Bolts. They are designed to be installed without

them. Note: ARP will NOT be responsible for any

failures resulting from using a washer with this kit.

[3] Make sure there is an adequate chamfer around the

bolt holes on the flywheel to clear the radius under

the head of the bolt.

[4] Lubricate the threads of the bolt with LOCTITE 242

and the under head of the bolt with ARP ULTRATORQUE

FASTENER ASSEMBLY LUBRICANT.

Then install the flywheel onto the crankshaft and

tighten the bolts hand tight.

[5] Using an alternating or criss cross pattern, torque the

bolts to 70 ft lbs using the specified lubricants

in Step 4."

-

PaulMK1 - Seasoned Racer

- Posts: 548

- Joined: Mon Apr 13, 2009 8:44 pm

- Location: Perth

Re: MK1 RS2000 project

Paul, Paul is correct. There was an earlier set of instructions that were around 70lb's with the the ARP goop as Australian stocks were quite old and we never go any new instructions through so when I rang Al at ARP to sort out the dramas we were having with the the goop getting sprayed out on to the clutch face. It was then that we worked out we were also over tightening them. He also recommended a process that the NASCAR guys were doing as they had similar issues, and that was to use Loctite on the threads and 30wt oil under the head face and to tighten them to the oil specification. Which is 64lb's. But if they're now saying 70lb's with 242 on the threads and goop I would do that but use oil under the head, but if you like I can phone Al and see if there are any changes

-

Danny M - Seasoned Racer

- Posts: 2743

- Joined: Sat Jan 07, 2006 8:24 am

- Location: Brisbane, Qld

Re: MK1 RS2000 project

Seen the same thing happen to my 6 bolt fly wheel.

It was the 2nd rebuild and the arp goop was spread around the flywheel bolts after coming off engine dyno. Re checked tourque to be OK(as per old spec sheet, didn't know new info), cleaned the fly wheel face, assembled AP button clutch , dropped engine in car, few spurts of the right pedal, then rattle, rattle, rattle,.

car on hoist, metal bits on the floor, take box out and find the AP button clutch has broken up(retaining springs/ dowels to outer edge of pressure plate had fractured). Take off clutch and find the flywheel is loose, 1x ARP bolt head snapped, 1x dowel flogged out, and remaining bolts finger tight (go figure, so this was my knocking noise. thank god it wasn't the bottom end again)

So have the S#!ts big time, buy in new billet lighten flywheel from UK (rwd motorsport), new ARP bolts, up size dowels, new Exedy button/ cushion clutch (designed for T6 falcons etc,which is going really good) have the assembly balanced (which didn't require much) and so far so good.

Then fitted c/r helicut t9 box with good bits inside (nice box to use)

All I can say Paul is, it f#@n gets to ya, but the challenge can be interesting

( I thought it was just me with these types of issues)

It was the 2nd rebuild and the arp goop was spread around the flywheel bolts after coming off engine dyno. Re checked tourque to be OK(as per old spec sheet, didn't know new info), cleaned the fly wheel face, assembled AP button clutch , dropped engine in car, few spurts of the right pedal, then rattle, rattle, rattle,.

car on hoist, metal bits on the floor, take box out and find the AP button clutch has broken up(retaining springs/ dowels to outer edge of pressure plate had fractured). Take off clutch and find the flywheel is loose, 1x ARP bolt head snapped, 1x dowel flogged out, and remaining bolts finger tight (go figure, so this was my knocking noise. thank god it wasn't the bottom end again)

So have the S#!ts big time, buy in new billet lighten flywheel from UK (rwd motorsport), new ARP bolts, up size dowels, new Exedy button/ cushion clutch (designed for T6 falcons etc,which is going really good) have the assembly balanced (which didn't require much) and so far so good.

Then fitted c/r helicut t9 box with good bits inside (nice box to use)

All I can say Paul is, it f#@n gets to ya, but the challenge can be interesting

( I thought it was just me with these types of issues)

- SimonG

- Starting out - Level 2S License

- Posts: 30

- Joined: Thu May 12, 2011 7:51 am

Re: MK1 RS2000 project

current issue, twisting axles ends...............

- SimonG

- Starting out - Level 2S License

- Posts: 30

- Joined: Thu May 12, 2011 7:51 am

Re: MK1 RS2000 project

My current issue is reliability - I haven't finished an event this year!

and i hope I don't have issues with my hilux axle ends!

and i hope I don't have issues with my hilux axle ends!

-

PaulMK1 - Seasoned Racer

- Posts: 548

- Joined: Mon Apr 13, 2009 8:44 pm

- Location: Perth

Re: MK1 RS2000 project

Given the shear size of the Hilux axles I would be amazed if an Escort twisted one.....well that's what I am hoping anyway.

1970 Mk1 Escort Tarmac Rally Car

Supported By:

Frank Reed Conveyancing

Loving Wife

Supported By:

Frank Reed Conveyancing

Loving Wife

- MK1_Oz

- Seasoned Racer

- Posts: 1655

- Joined: Tue Dec 02, 2008 4:05 pm

- Location: Adelaide

Re: MK1 RS2000 project

should have clarified, i am still using english set up

new tran x ones are in the mail.

Hilux conversion later on when i can do a full monty set up on the rear end

new tran x ones are in the mail.

Hilux conversion later on when i can do a full monty set up on the rear end

- SimonG

- Starting out - Level 2S License

- Posts: 30

- Joined: Thu May 12, 2011 7:51 am

Re: MK1 RS2000 project

Paul have you weighed the clutch and flywheel yet?

-

Danny M - Seasoned Racer

- Posts: 2743

- Joined: Sat Jan 07, 2006 8:24 am

- Location: Brisbane, Qld

Re: MK1 RS2000 project

The flywheel and crank are at teh machine shop being checked for square - hopefully back tomorrow or Friday.

The advertised weight is 3.2Kg (minus ring gear) - the clutch and pressure plate come to 5kg on the bathroom scales

The advertised weight is 3.2Kg (minus ring gear) - the clutch and pressure plate come to 5kg on the bathroom scales

-

PaulMK1 - Seasoned Racer

- Posts: 548

- Joined: Mon Apr 13, 2009 8:44 pm

- Location: Perth

Re: MK1 RS2000 project

Re Dipsticks:

I don't want to buy another dipstick from burtons to have the same issue re-occur. I have fitted a standard stick in the hole but am running the RS2000 alloy sump so potentially the length and levels will be different.

http://www.burtonpower.com/ft650.html

I did email burtons and ask for the length but they came back with "the levels on our dipstick and tube will be different to an other as they are a matched pair"http://www.burtonpower.com/catalogsearch/result/?q=rs2000+dipstick

Am I right in think I need to establish an high oil level in the sump that will be below the baffle (and therefore the crank)?

I don't want to buy another dipstick from burtons to have the same issue re-occur. I have fitted a standard stick in the hole but am running the RS2000 alloy sump so potentially the length and levels will be different.

http://www.burtonpower.com/ft650.html

I did email burtons and ask for the length but they came back with "the levels on our dipstick and tube will be different to an other as they are a matched pair"http://www.burtonpower.com/catalogsearch/result/?q=rs2000+dipstick

Am I right in think I need to establish an high oil level in the sump that will be below the baffle (and therefore the crank)?

-

PaulMK1 - Seasoned Racer

- Posts: 548

- Joined: Mon Apr 13, 2009 8:44 pm

- Location: Perth

Re: MK1 RS2000 project

Paul, I use the same sump (alloy rs) and the orginal dip stick (ridged type)

now by memory its 3.75lt capacity (corrections welcome) for an rs sump set up plus oil filter and engine components soak up, which meant the oil level was above the 'original fill line' when using a standard dip stick and steel sump.

Now since I was wary of what was supposed to be the correct level (and the fact I had oil pressure iusses, old long story) I measured this amount of oil in the pan which sits above the baffel, actually closer to the edge of the rear 1/2 moon seal of the sump. Then refitted the sump, filled oil, then marked the dip stick.

For me it's about the same amount of the low>full shade marking over and above again.

I also run a 19row oil cooler and 3/4 pint accusump, so its does fill the sump a bit higher if the accusump is fully discharged.

(Accusump is my engine insurance policy)

PS. I do like my pinto in full swing/ noise......escpecially when I am equal and sometimes better in times with gt4's, wrx's and evo's (don't mention the gtr's or sx180's no competition) and the like , BUT it does consume alot of my time.

Especially the current Esslinger Roller cam and constant clearance checking/ adjustments.

now by memory its 3.75lt capacity (corrections welcome) for an rs sump set up plus oil filter and engine components soak up, which meant the oil level was above the 'original fill line' when using a standard dip stick and steel sump.

Now since I was wary of what was supposed to be the correct level (and the fact I had oil pressure iusses, old long story) I measured this amount of oil in the pan which sits above the baffel, actually closer to the edge of the rear 1/2 moon seal of the sump. Then refitted the sump, filled oil, then marked the dip stick.

For me it's about the same amount of the low>full shade marking over and above again.

I also run a 19row oil cooler and 3/4 pint accusump, so its does fill the sump a bit higher if the accusump is fully discharged.

(Accusump is my engine insurance policy)

PS. I do like my pinto in full swing/ noise......escpecially when I am equal and sometimes better in times with gt4's, wrx's and evo's (don't mention the gtr's or sx180's no competition) and the like , BUT it does consume alot of my time.

Especially the current Esslinger Roller cam and constant clearance checking/ adjustments.

- SimonG

- Starting out - Level 2S License

- Posts: 30

- Joined: Thu May 12, 2011 7:51 am

Re: MK1 RS2000 project

For the alloy RS2000 alloy sump I have now been given the following dipstick measurements - can anyone verify?

The tube is 260mm in length,

the dipstick from the stop to the bottom is 415mm,

the max mark from the stop is 378mm, the min is 404mm

Cheers,

Paul.

The tube is 260mm in length,

the dipstick from the stop to the bottom is 415mm,

the max mark from the stop is 378mm, the min is 404mm

Cheers,

Paul.

-

PaulMK1 - Seasoned Racer

- Posts: 548

- Joined: Mon Apr 13, 2009 8:44 pm

- Location: Perth

Re: MK1 RS2000 project

Thanks to the excellent photographers out there last week I now have access to some good pictures prior to my escort falling apart:

http://www.pixelculture.com/?page_id=13986

Nicely glued to the road:

http://www.pixelculture.com/?page_id=13986

Nicely glued to the road:

-

PaulMK1 - Seasoned Racer

- Posts: 548

- Joined: Mon Apr 13, 2009 8:44 pm

- Location: Perth

Re: MK1 RS2000 project

Great shots Paul, looks like you're really trying hard.

And the link was good too, with a great selection of cars competing and they all look well presented, no dungers at all! Thanks.

And the link was good too, with a great selection of cars competing and they all look well presented, no dungers at all! Thanks.

-

Darren W. - Seasoned Racer

- Posts: 798

- Joined: Fri Apr 04, 2008 8:03 pm

- Location: North Brisbane

Re: MK1 RS2000 project

Paul have you put hte sump on yet?

If you haven't and if you're windage tray mounts off the bottom of the main caps I would stick the stick in without the sump on and mark say 10m from the bottom of the tray or below the crank/rod and go from there

If you haven't and if you're windage tray mounts off the bottom of the main caps I would stick the stick in without the sump on and mark say 10m from the bottom of the tray or below the crank/rod and go from there

-

Danny M - Seasoned Racer

- Posts: 2743

- Joined: Sat Jan 07, 2006 8:24 am

- Location: Brisbane, Qld

Re: MK1 RS2000 project

Funnily enough I have everything I need to re-assemble now except for the sump gasket...

I'll take plenty of measurements before final refit.

I'll take plenty of measurements before final refit.

-

PaulMK1 - Seasoned Racer

- Posts: 548

- Joined: Mon Apr 13, 2009 8:44 pm

- Location: Perth

Return to Members Cars / Projects

Who is online

Users browsing this forum: No registered users and 7 guests