MK1 RS2000 project

Moderator: Moderators

Re: MK1 RS2000 project

Tomorrow is my first trip to Barbagallo Raceway in my Esky for the VSCC Stampede

http://www.vsccwa.com.au/cms/index.php? ... e-stampede

Looking at the Team entries we seem to have a fair number of Escorts, Cortinas and Falcons. The opposition seems to be mainly Datsun Z's and clubmans. Pictures will follow tomorrow night/Monday.

Next week the Xmas freshen up will start, with the engine, pedal box and front suspension being the main focus.

http://www.vsccwa.com.au/cms/index.php? ... e-stampede

Looking at the Team entries we seem to have a fair number of Escorts, Cortinas and Falcons. The opposition seems to be mainly Datsun Z's and clubmans. Pictures will follow tomorrow night/Monday.

Next week the Xmas freshen up will start, with the engine, pedal box and front suspension being the main focus.

-

PaulMK1 - Seasoned Racer

- Posts: 548

- Joined: Mon Apr 13, 2009 8:44 pm

- Location: Perth

Re: MK1 RS2000 project

Here's a few videos. They ran 6 events with a rolling start and approx 6 laps each. My car was quick through the esses and over skyline into colb but as you will see I lacked HP along the straights. As the day went on my lines and confidence did improve...

In-car:

http://youtu.be/CDRcM_yRtK4

http://youtu.be/sd2iQ9jD-rQ

http://youtu.be/dqB8aB4htr0

In-car:

http://youtu.be/CDRcM_yRtK4

http://youtu.be/sd2iQ9jD-rQ

http://youtu.be/dqB8aB4htr0

-

PaulMK1 - Seasoned Racer

- Posts: 548

- Joined: Mon Apr 13, 2009 8:44 pm

- Location: Perth

Re: MK1 RS2000 project

I have decided to re-fresh the existing car and keep the grey/orange shell duratec project on the back burner for the time being.

On the list is:

1) Freshen up the engine

2) Replace the RD pedal box that is falling apart

3) Change the rear calipers

4) maybe paint

So tonight the engine came out - it's been hemridging oil for the past few events leaving 20cm puddles of oil after a hard run and I’m also getting quite a bit of blow-by into the catch tank now.

It looks like the rear seal:

Two of the clutch center springs were broken and the surface has some wierd marks:

I'll whip the head and sump off tomorrow night and then I'll put together the shopping list. Currently bearings, rings and HP oil pump. I hope their are no nasty surprises inside...

On the list is:

1) Freshen up the engine

2) Replace the RD pedal box that is falling apart

3) Change the rear calipers

4) maybe paint

So tonight the engine came out - it's been hemridging oil for the past few events leaving 20cm puddles of oil after a hard run and I’m also getting quite a bit of blow-by into the catch tank now.

It looks like the rear seal:

Two of the clutch center springs were broken and the surface has some wierd marks:

I'll whip the head and sump off tomorrow night and then I'll put together the shopping list. Currently bearings, rings and HP oil pump. I hope their are no nasty surprises inside...

-

PaulMK1 - Seasoned Racer

- Posts: 548

- Joined: Mon Apr 13, 2009 8:44 pm

- Location: Perth

Re: MK1 RS2000 project

The head is off - good news is 44.5 inlets, and 38 exhausts and good looking ports.

Bad news is 38cc chambers and which seem to give a compression of 12.97:1 which would explain the det I have experienced.

which would explain the det I have experienced.

The old head gasket ring measures 1.2mm thick uncompressed - is that safe to use for my calcs, or do they decompress?

Whats a safe ratio to run on pump 98ron? If I fit a .080" MLS-5 GASKET it comes down to 11.6:1

Everything else looks fine - the gasket has blown threw two water courses which I suspect shouldn't have been blanked:

Intake:

CC-ing:

Now I need to chase the missing HP since all the components look good on paper...

Bad news is 38cc chambers and which seem to give a compression of 12.97:1

The old head gasket ring measures 1.2mm thick uncompressed - is that safe to use for my calcs, or do they decompress?

Whats a safe ratio to run on pump 98ron? If I fit a .080" MLS-5 GASKET it comes down to 11.6:1

Everything else looks fine - the gasket has blown threw two water courses which I suspect shouldn't have been blanked:

Intake:

CC-ing:

Now I need to chase the missing HP since all the components look good on paper...

-

PaulMK1 - Seasoned Racer

- Posts: 548

- Joined: Mon Apr 13, 2009 8:44 pm

- Location: Perth

Re: MK1 RS2000 project

you wont get an acurate CC reading like that

you need to stick a pce of perspex with a small hole

in it to fill with

on to the head

with grease or silicone

then fill with brake fluid or glycerine (better than water)

all this is to do with the "mamiscous effect"

hope i spelt that right

you need to stick a pce of perspex with a small hole

in it to fill with

on to the head

with grease or silicone

then fill with brake fluid or glycerine (better than water)

all this is to do with the "mamiscous effect"

hope i spelt that right

STEVE KING mk 1 rs2000

-

gen mk 1rs2000 - Seasoned Racer

- Posts: 2194

- Joined: Wed Oct 04, 2006 9:57 pm

- Location: gold coast aus

Re: MK1 RS2000 project

That is brake fluid - and 1cc more it overflows...

I'll try and source some perspex tomorrow and try again your way and see what difference I get since I agree that was "doming" a bit

I'll try and source some perspex tomorrow and try again your way and see what difference I get since I agree that was "doming" a bit

-

PaulMK1 - Seasoned Racer

- Posts: 548

- Joined: Mon Apr 13, 2009 8:44 pm

- Location: Perth

Re: MK1 RS2000 project

Paul yeah you really need to use a bit of perspex like Steve has said as you wont get an accurate reading otherwise also that isn't a Felpro head gasket and if it came off at 1.2mm thats what it is as they generally stay squashed, with a Felpro it may increase the ratio a little as well

-

Danny M - Seasoned Racer

- Posts: 2743

- Joined: Sat Jan 07, 2006 8:24 am

- Location: Brisbane, Qld

Re: MK1 RS2000 project

Danny: That gasket came with a mate's Kent Cam kit - its was a 93mm bore strangely enough.

I carried on stripping the car today and re-tested the CC using the perspex top plate sealed with grease and got 37cc

I think Glenn was enquiring about rear calipers - these are R31 silver and VN Orange (said red on the can)

Old Pedal box (left) next to the new pedal box (right)

(I have yet to modify the loud pedal to desired position)

I have the block on the stand now ready to remove pistons and crank

I carried on stripping the car today and re-tested the CC using the perspex top plate sealed with grease and got 37cc

I think Glenn was enquiring about rear calipers - these are R31 silver and VN Orange (said red on the can)

Old Pedal box (left) next to the new pedal box (right)

(I have yet to modify the loud pedal to desired position)

I have the block on the stand now ready to remove pistons and crank

-

PaulMK1 - Seasoned Racer

- Posts: 548

- Joined: Mon Apr 13, 2009 8:44 pm

- Location: Perth

Re: MK1 RS2000 project

looks like a few air bubbles in the perspex , i have the head on a slight angle with the hole at the highest point to avoid the bubbles

-

joe84 - Open - C4 License

- Posts: 316

- Joined: Fri Jan 19, 2007 9:41 pm

- Location: bris , qld

Re: MK1 RS2000 project

The first time I tried I got massive air bubbles around the outside. I then reversed the perspex and got the same again - so in the picture you can see four smaller holes round the edges which fixed that issue. I'm getting 37 & 38cc on every cylinder using each method. So I reckon it's correct within +/- 1cc

-

PaulMK1 - Seasoned Racer

- Posts: 548

- Joined: Mon Apr 13, 2009 8:44 pm

- Location: Perth

Re: MK1 RS2000 project

i cant remember the calculation ?

but how much does 1 cc change the compression ration figure?

but how much does 1 cc change the compression ration figure?

STEVE KING mk 1 rs2000

-

gen mk 1rs2000 - Seasoned Racer

- Posts: 2194

- Joined: Wed Oct 04, 2006 9:57 pm

- Location: gold coast aus

Re: MK1 RS2000 project

1cc makes .18 diff so i'm either 12.92:1 or 13.2:1 either is way too high for 89RON

Engine is now stripped and ready to be dropped off to the machine shop.

The mains look perfect, but the big ends are showing some signs of wear:

Also is this normal for the top edges?

Bores look OK so hopefully i'll get away with a light hone:

Engine is now stripped and ready to be dropped off to the machine shop.

The mains look perfect, but the big ends are showing some signs of wear:

Also is this normal for the top edges?

Bores look OK so hopefully i'll get away with a light hone:

-

PaulMK1 - Seasoned Racer

- Posts: 548

- Joined: Mon Apr 13, 2009 8:44 pm

- Location: Perth

Re: MK1 RS2000 project

Interesting watching the videos, and how things improved.

I noticed you realised after a few runs that you can carry a higher gear than you initially expect through the left hander up the hill.

I reckon there is time to be gained by braking later into kolb (tricky corner to judge the downhill braking point, where to position the car on entry, and where the apex is) and especially more time on ford fast brake (the one leading onto pit straight) where you can leave the braking until somewhere up the rise into the corner.

Get those two corners right and you make up huge chunks of time.

Now all I need to do is follow my own advice!

Oh and Paul I have a big valve head I no longer need. Would fit your valves - I ran 44.5mm and 38mm in it. Would need a freshen up with valve seats recut but it hasn't been skimmed much if at all. PM me for more info.

I noticed you realised after a few runs that you can carry a higher gear than you initially expect through the left hander up the hill.

I reckon there is time to be gained by braking later into kolb (tricky corner to judge the downhill braking point, where to position the car on entry, and where the apex is) and especially more time on ford fast brake (the one leading onto pit straight) where you can leave the braking until somewhere up the rise into the corner.

Get those two corners right and you make up huge chunks of time.

Now all I need to do is follow my own advice!

Oh and Paul I have a big valve head I no longer need. Would fit your valves - I ran 44.5mm and 38mm in it. Would need a freshen up with valve seats recut but it hasn't been skimmed much if at all. PM me for more info.

- Avon

- P Plater - C3 License

- Posts: 60

- Joined: Sat Apr 22, 2006 8:42 am

- Location: Perth

Re: MK1 RS2000 project

If you watch I was being passed about 200m past kolb, and 100m onto the pit straight. It has been suggested it was because I was diving down the inside on brakes and therefore was later on the accelerator out of both corners. The ideal line is a much wider entry, power on early with a later apex - oh well maybe next year!

-

PaulMK1 - Seasoned Racer

- Posts: 548

- Joined: Mon Apr 13, 2009 8:44 pm

- Location: Perth

Re: MK1 RS2000 project

I think I may have found some of my missing ponies....

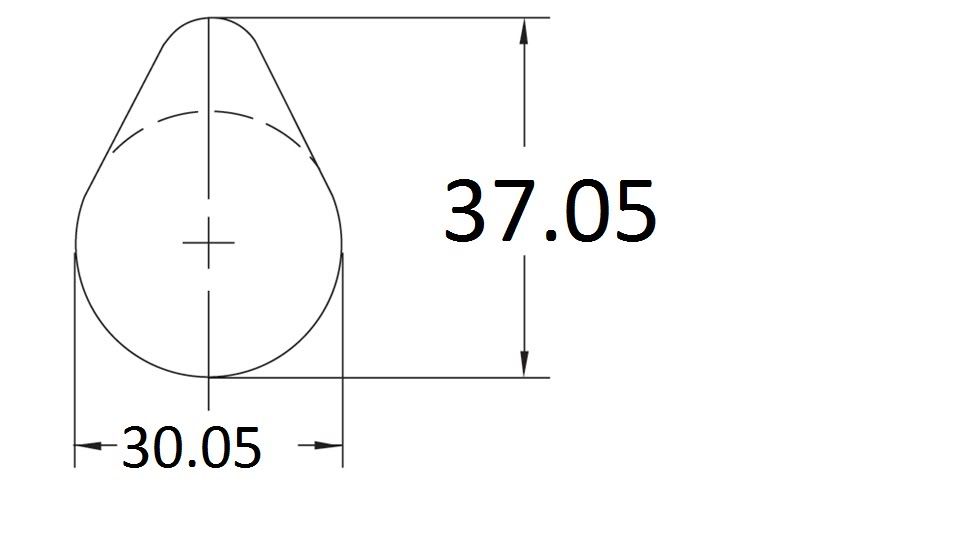

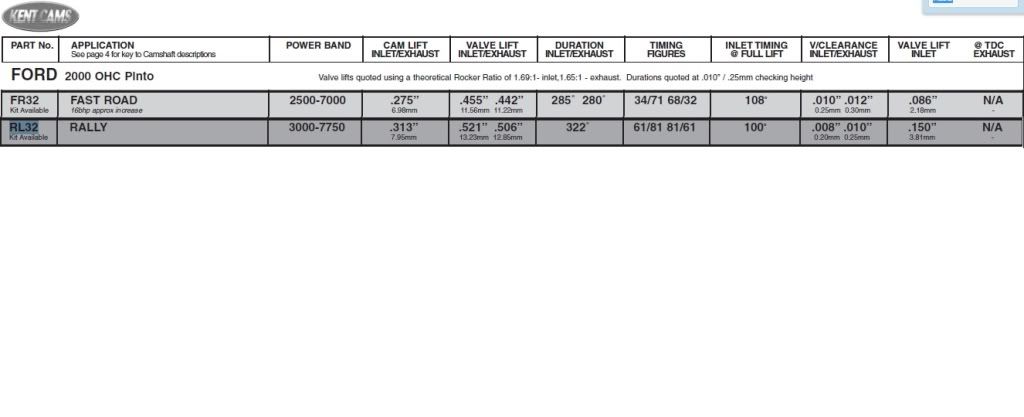

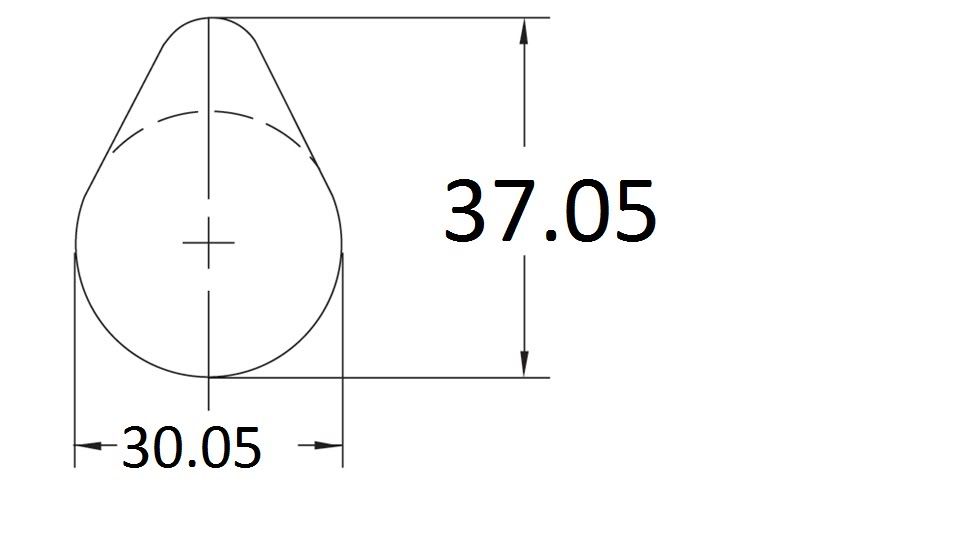

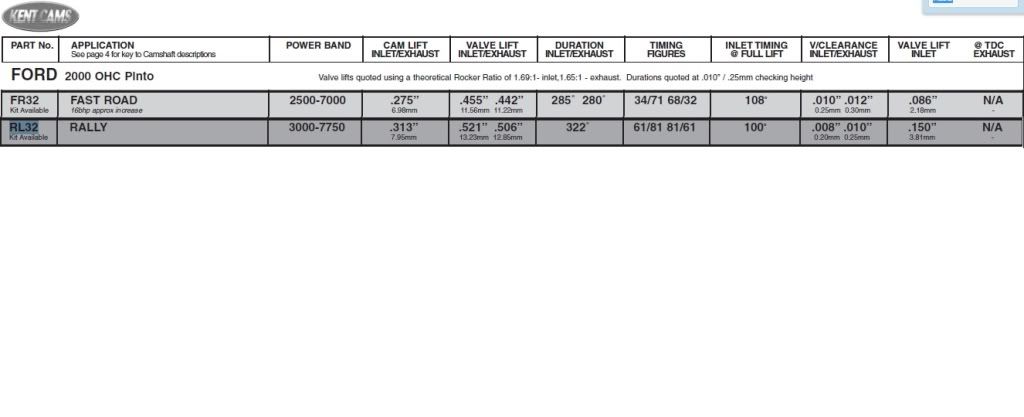

My cam reports to being a RL32:

The Kent spec for a RL32 is:

Camlift: 7.95mm

Valve lift: 13.23mm

With the dial guage on the cam lobes I only got 273" (6.7mm) so I then checked by measuring the base circle vs lobe height and got a similiar reading:

I then rolled the head over and move the dial guage to the inlet valve and got 0.45" (11.5mm)

So my cam looks a lot more like a FR32 but has been dialled in to the RL32 timings:

Bugger!!!

My cam reports to being a RL32:

The Kent spec for a RL32 is:

Camlift: 7.95mm

Valve lift: 13.23mm

With the dial guage on the cam lobes I only got 273" (6.7mm) so I then checked by measuring the base circle vs lobe height and got a similiar reading:

I then rolled the head over and move the dial guage to the inlet valve and got 0.45" (11.5mm)

So my cam looks a lot more like a FR32 but has been dialled in to the RL32 timings:

Bugger!!!

-

PaulMK1 - Seasoned Racer

- Posts: 548

- Joined: Mon Apr 13, 2009 8:44 pm

- Location: Perth

Re: MK1 RS2000 project

That would explain a lot!

Dial gauges are great

One last thing to do before you chuck it would be to test the duration - this is a good pattern

http://www.tavia.com/free_degree_wheel.html

Dial gauges are great

One last thing to do before you chuck it would be to test the duration - this is a good pattern

http://www.tavia.com/free_degree_wheel.html

- Avon

- P Plater - C3 License

- Posts: 60

- Joined: Sat Apr 22, 2006 8:42 am

- Location: Perth

Re: MK1 RS2000 project

Happy New Year All!

My 2 week break has been spent mostly non-car focused painting, tiling, roofing, etc. Anyhow today I finally got to do some interesting stuff...

I recently bought some new shelving for the shed so had a load of MDF left over so today I built:

It's a two chamber flow bench with a 63mm orifice. Currently it just has the one manometer measuring vacuum but I have room to add a Inclined manometer for better adjustment.

I currently have 4 pinto cylinder heads - so to test the theory I first placed my big valve big port FR32 head with an inlet fully open, and then repeated the test with a standard head, standard cam with an inlet fully open.

The small pencil marks on the left are the difference between the two heads.

The theory is based on:

http://www.dtec.net.au/Tech%20Articles/ ... Design.pdf

I'll have a good read over the weekend and see if I can get a better scale working.

My 2 week break has been spent mostly non-car focused painting, tiling, roofing, etc. Anyhow today I finally got to do some interesting stuff...

I recently bought some new shelving for the shed so had a load of MDF left over so today I built:

It's a two chamber flow bench with a 63mm orifice. Currently it just has the one manometer measuring vacuum but I have room to add a Inclined manometer for better adjustment.

I currently have 4 pinto cylinder heads - so to test the theory I first placed my big valve big port FR32 head with an inlet fully open, and then repeated the test with a standard head, standard cam with an inlet fully open.

The small pencil marks on the left are the difference between the two heads.

The theory is based on:

http://www.dtec.net.au/Tech%20Articles/ ... Design.pdf

I'll have a good read over the weekend and see if I can get a better scale working.

-

PaulMK1 - Seasoned Racer

- Posts: 548

- Joined: Mon Apr 13, 2009 8:44 pm

- Location: Perth

Re: MK1 RS2000 project

Nice work!

1970 Mk1 Escort Tarmac Rally Car

Supported By:

Frank Reed Conveyancing

Loving Wife

Supported By:

Frank Reed Conveyancing

Loving Wife

- MK1_Oz

- Seasoned Racer

- Posts: 1655

- Joined: Tue Dec 02, 2008 4:05 pm

- Location: Adelaide

Re: MK1 RS2000 project

In proudly showing my wife my new contraption I discovered the old standard head was missing the spark plug

So with the plug installed I get 12mm difference in flow which is much better

I have been reading about 10" of water - does this mean 5" each side of the manometer?

So with the plug installed I get 12mm difference in flow which is much better

I have been reading about 10" of water - does this mean 5" each side of the manometer?

-

PaulMK1 - Seasoned Racer

- Posts: 548

- Joined: Mon Apr 13, 2009 8:44 pm

- Location: Perth

Re: MK1 RS2000 project

I finally got to work on the car again:

First was the inner wing where fuel and oil had removed all the paint:

So a good scrub, etch prime and blow over got it looking good again:

I've also fixed up the bulkhead around the old brake reservoirs, stripped the wiring harness of unused wires and re-taped, and generally fixed up the bay. Pictures will have to follow.

The stripped starter thread in the bell housing has been repaired (steel insert) and I discovered the cable was not pulling straight on the fork so have adapted the plate and made a spacer on the pivot to try and limit the free play.

The new cam, HP oil pump and extractors have arrived. I have put the flow bench to good use and am now happy that the new CNC head is indeed significantly better than my current big port, big valve. I'm still waiting on the machine shop to return the block but at least that is keeping me focused elsewhere.

First was the inner wing where fuel and oil had removed all the paint:

So a good scrub, etch prime and blow over got it looking good again:

I've also fixed up the bulkhead around the old brake reservoirs, stripped the wiring harness of unused wires and re-taped, and generally fixed up the bay. Pictures will have to follow.

The stripped starter thread in the bell housing has been repaired (steel insert) and I discovered the cable was not pulling straight on the fork so have adapted the plate and made a spacer on the pivot to try and limit the free play.

The new cam, HP oil pump and extractors have arrived. I have put the flow bench to good use and am now happy that the new CNC head is indeed significantly better than my current big port, big valve. I'm still waiting on the machine shop to return the block but at least that is keeping me focused elsewhere.

-

PaulMK1 - Seasoned Racer

- Posts: 548

- Joined: Mon Apr 13, 2009 8:44 pm

- Location: Perth

Return to Members Cars / Projects

Who is online

Users browsing this forum: No registered users and 6 guests