My new pinto engine build

I got a pinto to rebuild which had been run with little more than litre of oil in the sump. The engine had been loosing or burning oil but it was not obvious as the top of the dipstick had worked loose so each time it was dipped the dipsitick pushed a little further into the sump and registered ok. The engine finally gave up a mile into a rally when the oil pressure started jumping around and it began to tighten up and make some bad sounds.

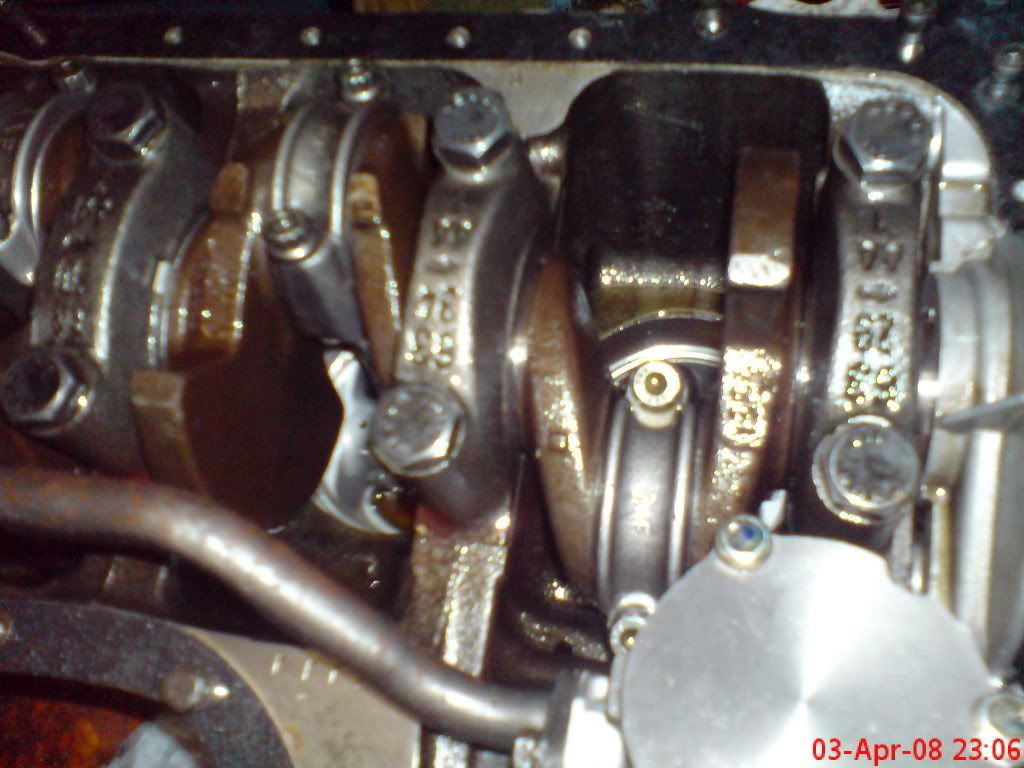

I started the strip down and found that 6 of the cam followers were so badly worn that they could easily have been removed without loosening the adjusters. The cam lobes were in surprisingly good shape with only some scoring on two of the lobes. However the groove at the end of the cam for holding it in place had worn badly so that it could be pushed forward or backwards by a few mm.

Worn followers :note the mismatched one at the end

Scored cam lobe

Worn retaining groove

I stripped the bottom end and found some more surprises. The first thing was one conrod which was different to the other three. All were manufactured by Farndon and were the same lenght but one was 2mm narrower at the big end than the others (not worn but machined to this width) The big end bearings were showing some signs of wear but not too much but the centre main bearing was very badly worn. Possibly caused bu the imbalance caused by the ligher conrod.

Two different conrods

Compression ratio 11:1, Cam is Kent GTS4 and pistons are forged Acralite. The bores looked very glazed. The valve guides were a little worn and all valve seals were lifted but the centre spring of the double valve springs.

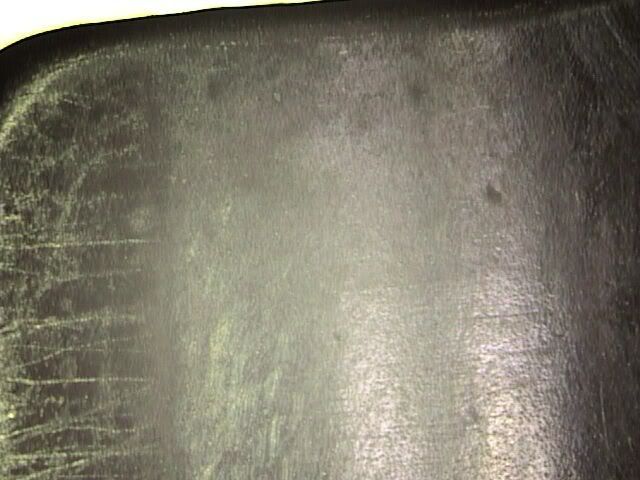

Looking down into the bore. Lots of carbon builbup

I have a few questions for later

Tom

I started the strip down and found that 6 of the cam followers were so badly worn that they could easily have been removed without loosening the adjusters. The cam lobes were in surprisingly good shape with only some scoring on two of the lobes. However the groove at the end of the cam for holding it in place had worn badly so that it could be pushed forward or backwards by a few mm.

Worn followers :note the mismatched one at the end

Scored cam lobe

Worn retaining groove

I stripped the bottom end and found some more surprises. The first thing was one conrod which was different to the other three. All were manufactured by Farndon and were the same lenght but one was 2mm narrower at the big end than the others (not worn but machined to this width) The big end bearings were showing some signs of wear but not too much but the centre main bearing was very badly worn. Possibly caused bu the imbalance caused by the ligher conrod.

Two different conrods

Compression ratio 11:1, Cam is Kent GTS4 and pistons are forged Acralite. The bores looked very glazed. The valve guides were a little worn and all valve seals were lifted but the centre spring of the double valve springs.

Looking down into the bore. Lots of carbon builbup

I have a few questions for later

Tom